Choosing the Right Equipment

June 08, 2022

An industrial floor sweeper or scrubber is an investment that requires research and planning. Choosing the wrong machine can affect labor costs, maintenance costs, operating costs and down-time. There are several variables to be considered when choosing your cleaning equipment: total square footage of the facility, cleanable square footage, aisle width, floor condition, debris conditions, usage frequency, your labor rate and the initial purchase price of the machine. Skipping straight to the purchase price without considering any other variables could cause major problems in the future.

Sweeping vs. Scrubbing

Sweeping | |

Pros

| Cons

|

Scrubbing | |

Pros

| Cons

|

Power Types

Battery

Battery powered cleaning equipment tend to cost less to operate and maintain, but there is a performance trade-off. Most battery equipment is limited to 2-5 hours of run time, depending on the machine and operating choices. This may be fine for your application depending on the size of the machine you choose. When selecting a battery machine, you also have to consider battery maintenance since the battery is most likely the most expensive component on the machine.

Engine

Engine powered equipment gives you the ability to extend run-times to fit with your operational needs. Most of our equipment is available in LP, gasoline & diesel. There are some health considerations when choosing your fuel type as gasoline and diesel should not be used in confined areas. Engine powered equipment tends to be more maintenance intensive, is louder when operating and usually doesn't have the same lifespan as a battery machine.

Hybrid

Nilfisk-Advance is the only manufacturer of industrial cleaning equipment that is manufacturing hybrid equipment. You get the best of both worlds by reducing your fuel costs and extending your run-times. These machines utilize all electric drives that can be ran off the battery when the equipment runs out of fuel. This allows you to utilize all the fuel in an LP tank while also extending how long that tank lasts. Ask for a fuel savings calculation when considering a hybrid to see what you could save.

Walking vs. Riding

Walking

Walk behind cleaning equipment is usually selected to clean smaller facilities or areas that are hard to maneuver with large equipment. Some might be tempted to choose a walk behind machine to clean a larger facility due to the lower purchase price, but this is just a substitution of costs. You benefit from the lower purchase price in the beginning, but you are hampered by the reduced life of the equipment, poor performance and increased down-time. It is more appropriate to supplement larger equipment with a walk-behind to reach areas where a rider might not be capable.

With a large walk-behind scrubber, cleaning will take longer than the same size rider. You can only run the machine at a speed that an operator can sustain. Operators using a walk behind scrubber are subject to fatigue from not just the walking but also turning the machine. The larger the walk behind scrubber, the more force is required by the operator to execute a turn.

Riding

Ride-on equipment is usually selected to clean areas that are too large to clean effectively with walk-behind equipment. Riding equipment also reduces the fatigue that comes from cleaning with a walk-behind machine. This may also contribute to people being more willing to volunteer to clean in your facility.

While it is true that a walk-behind is more maneuverable than a large rider machine, it is not true when the machines have the same scrub path. A 32" walk behind scrubber actually has a wider turning radius than a 32" rider. Many people choose small riders due to their high maneuverability. Using a rider of the same size will also reduce the time it takes to clean, since a rider can clean effectively at a higher rate of speed and can sustain it for a longer period of time. An operator using a rider scrubber has far less fatigue and will likely feel fresh when the cleaning task is complete and a new task must be started.

Cleaning Path Sizes

The width of scrubber you select can greatly impact the cost to operate your floor scrubber. This is true when you consider your cleanable square footage, but perhaps more important when you consider the width of your aisles. The number of passes down your aisle impact the time it takes to clean them.

Lets consider a scenario where a company has 10.5 foot wide aisles (126 inches). If you decided to purchase a 40″ ride on floor scrubber it would take you 4 passes to clean the aisle (with a 2 inch overlap). If you purchased the same scrubber with a 45″ scrub deck, you could complete the aisle in 3 passes and you wouldn’t have to be as precise as the previous 2″ overlap. This could save you a lot of money over the life of the machine and the additional 5″ inches of scrub width might only cost you an additional $2,000. It is important to consider the scrub width since many floor scrubbers over a range of scrub widths, and adding a larger scrub deck might not cost that much.

Lets consider a scenario where a company has 10.5 foot wide aisles (126 inches). If you decided to purchase a 40″ ride on floor scrubber it would take you 4 passes to clean the aisle (with a 2 inch overlap). If you purchased the same scrubber with a 45″ scrub deck, you could complete the aisle in 3 passes and you wouldn’t have to be as precise as the previous 2″ overlap. This could save you a lot of money over the life of the machine and the additional 5″ inches of scrub width might only cost you an additional $2,000. It is important to consider the scrub width since many floor scrubbers over a range of scrub widths, and adding a larger scrub deck might not cost that much.

Thinking about a scrubber...which scrub deck is best?

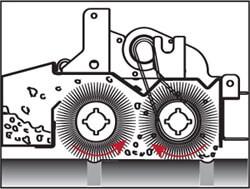

Cylindrical

Cylindrical floor scrubber decks utilize two brushes that span the width of the scrub deck. These two brushes work together to feed debris between them and into a debris catch bin that is mounted behind the scrub deck. The debris bin can be easily removed and dumped. By picking up debris as you scrub with a cylindrical scrubber, you reduce the chance of the squeegee blade becoming fouled/torn as well as reduce the chance of the squeegee hose becoming clogged. This is the main reason why most industrial applications utilize cylindrical scrub decks.

Cylindrical floor scrubber decks utilize two brushes that span the width of the scrub deck. These two brushes work together to feed debris between them and into a debris catch bin that is mounted behind the scrub deck. The debris bin can be easily removed and dumped. By picking up debris as you scrub with a cylindrical scrubber, you reduce the chance of the squeegee blade becoming fouled/torn as well as reduce the chance of the squeegee hose becoming clogged. This is the main reason why most industrial applications utilize cylindrical scrub decks.

Cylindrical scrub decks also clean better when your concrete floors that have a lot of wear. The cylindrical bristles reach into crevices and low spots better. Cylindrical brushes also turn at a faster rate which will remove some debris better.

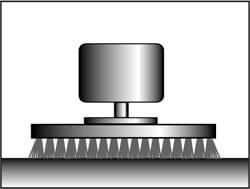

Disk

A disk scrub deck uses one, two or three flat brushes to clean the floor. A disk scrub deck is best when you have no debris on the floor and have a smooth, flat surface. Disk scrub decks are usually used in commercial applications where debris is not present. A disk scrub deck provides the most down pressure when cleaning.

A disk scrub deck uses one, two or three flat brushes to clean the floor. A disk scrub deck is best when you have no debris on the floor and have a smooth, flat surface. Disk scrub decks are usually used in commercial applications where debris is not present. A disk scrub deck provides the most down pressure when cleaning.

Machines with a disk scrub deck are also typically less expensive to purchase, but when placed into an industrial application, they are typically the most expensive to maintain. If you have any debris on the floor, the disk scrub brushes will allow the debris to pass through to the squeegee assembly. At this point the debris can damage the squeegee blades, foul the blades so that they allow dirty streaks to form, create a blockage in your recovery hose or make it into your recovery tank and possibly clog your drain hose.

Still have questions?

Contact a territory manager for a free site survey and product recommendation.

Request a Site Survey